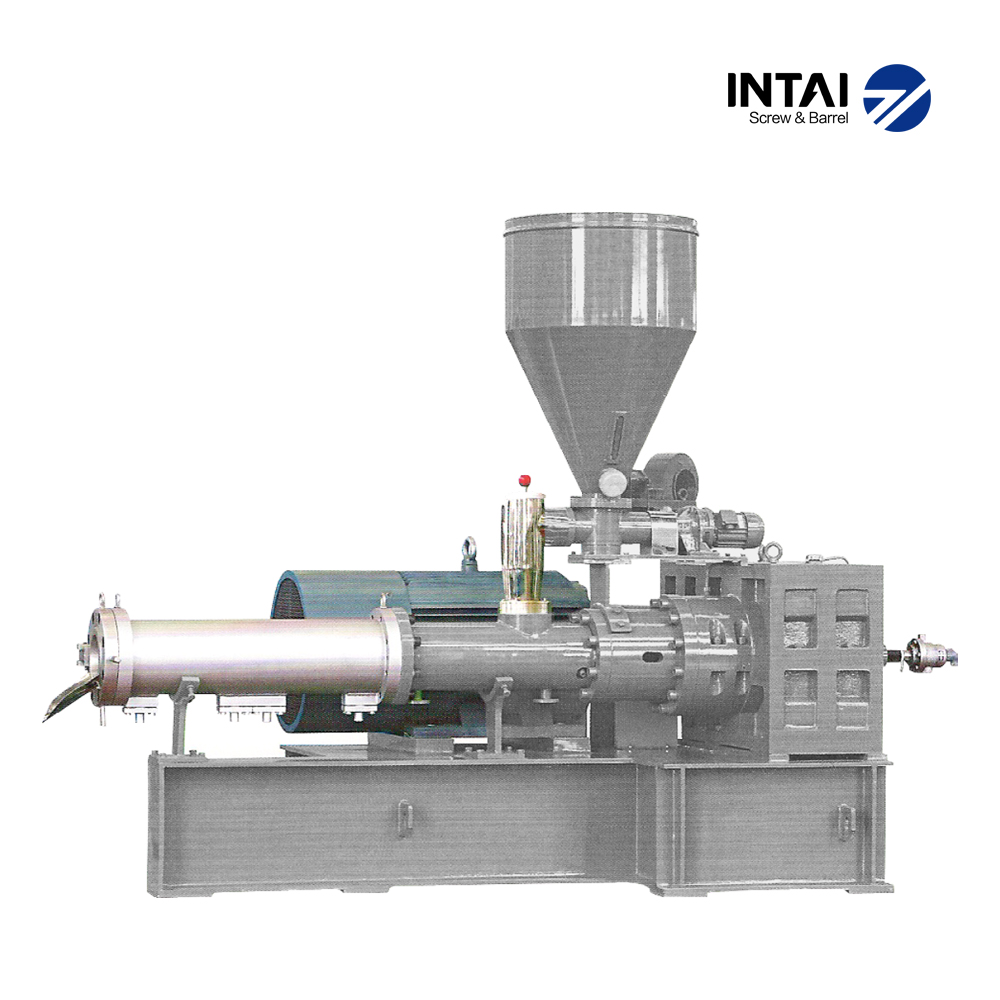

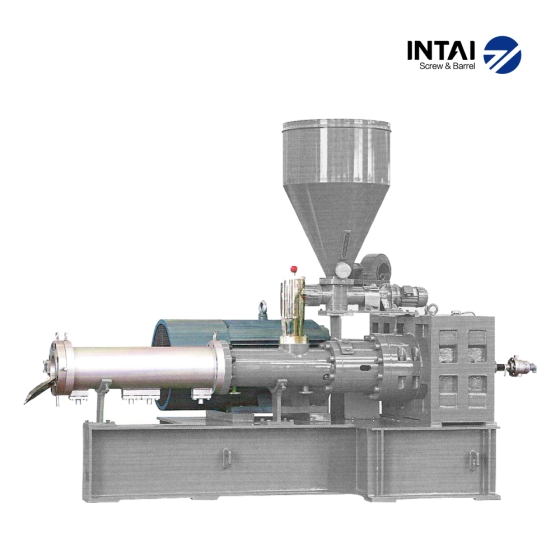

这 行星螺杆挤出机 是一种专门用于生产 PVC管材, 简介, 床单, 和电影. 其行星螺杆设计改善混合并确保均匀塑化. 通过降低剪切应力, 它保持挤出稳定并提高产品一致性. 这种结构还提高了表面质量和尺寸精度, 即使是大批量生产.

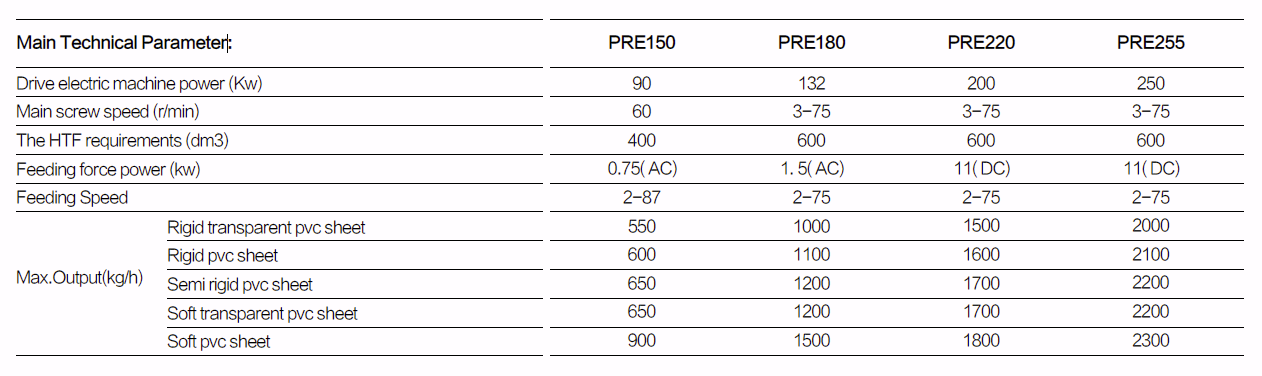

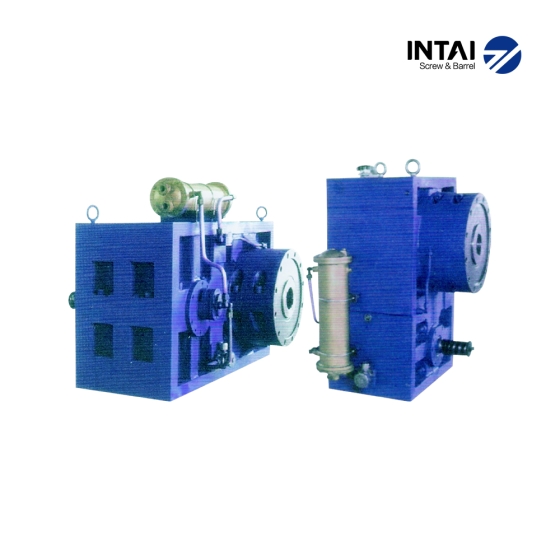

Intai 制造行星螺杆挤出机 合金钢, 数控加工, 和先进的表面处理 例如氮化和双金属涂层. 这些技术增加了耐磨性和腐蚀保护. 挤出机可处理多种原材料, 包括再生塑料和高填料化合物. 因此, 制造商获得较长的使用寿命, 减少停机时间, 并降低成本.

拥有超过 20 多年的行业经验和认证 CE, 德国莱茵TÜV, 英国标准协会, 和英国皇家认可委员会, Intai 提供深受客户信赖的挤出设备 20 国家. 查看我们的全系列产品 产品 目录, 或检查 国际标准化组织标准 为实现全球合规性. 英泰不断创新, 确保行星螺杆挤出机提供可靠的性能并满足全球塑料加工行业不断变化的需求.

这 行星螺杆挤出机 是一种专门用于生产 PVC管材, 简介, 床单, 和电影. 其行星螺杆设计改善混合并确保均匀塑化. 通过降低剪切应力, 它保持挤出稳定并提高产品一致性. 这种结构还提高了表面质量和尺寸精度, 即使是大批量生产.

Intai 制造行星螺杆挤出机 合金钢, 数控加工, 和先进的表面处理 例如氮化和双金属涂层. 这些技术增加了耐磨性和腐蚀保护. 挤出机可处理多种原材料, 包括再生塑料和高填料化合物. 因此, 制造商获得较长的使用寿命, 减少停机时间, 并降低成本.

拥有超过 20 多年的行业经验和认证 CE, 德国莱茵TÜV, 英国标准协会, 和英国皇家认可委员会, Intai 提供深受客户信赖的挤出设备 20 国家. 查看我们的全系列产品 产品 目录, 或检查 国际标准化组织标准 为实现全球合规性. 英泰不断创新, 确保行星螺杆挤出机提供可靠的性能并满足全球塑料加工行业不断变化的需求.

Q1: 英泰螺杆机筒采用什么材质?

A1: 我们使用带有氮化或双金属涂层的高级合金钢,以确保耐磨性, 腐蚀保护, 使用寿命长.

Q2: 你们可以生产定制螺杆机筒吗?

A2: 是的, 我们设计和制造圆锥形, 平行线, 单身的, 和双金属螺杆机筒根据客户规格用于挤出和注塑.

第三季度: 你们的产品适合哪些行业和应用?

A3: 英泰螺杆机筒广泛应用于塑料挤出和注射, 包括PVC管, 简介, 床单, 木塑产品, 和塑料回收.

第四季度: 交货时间是多长?

A4: 标准型号可在 20-30 天内供货. 定制产品取决于规格, 我们的团队将与您确认确切的交货时间.

Q5: 你们提供质量认证吗?

A5: 是的, 我们的产品已通过CE认证, 德国莱茵TÜV, 英国标准协会, 和英国皇家认可委员会, 并可根据要求提供详细的检验报告.

英泰螺丝制造厂

英泰螺丝制造厂