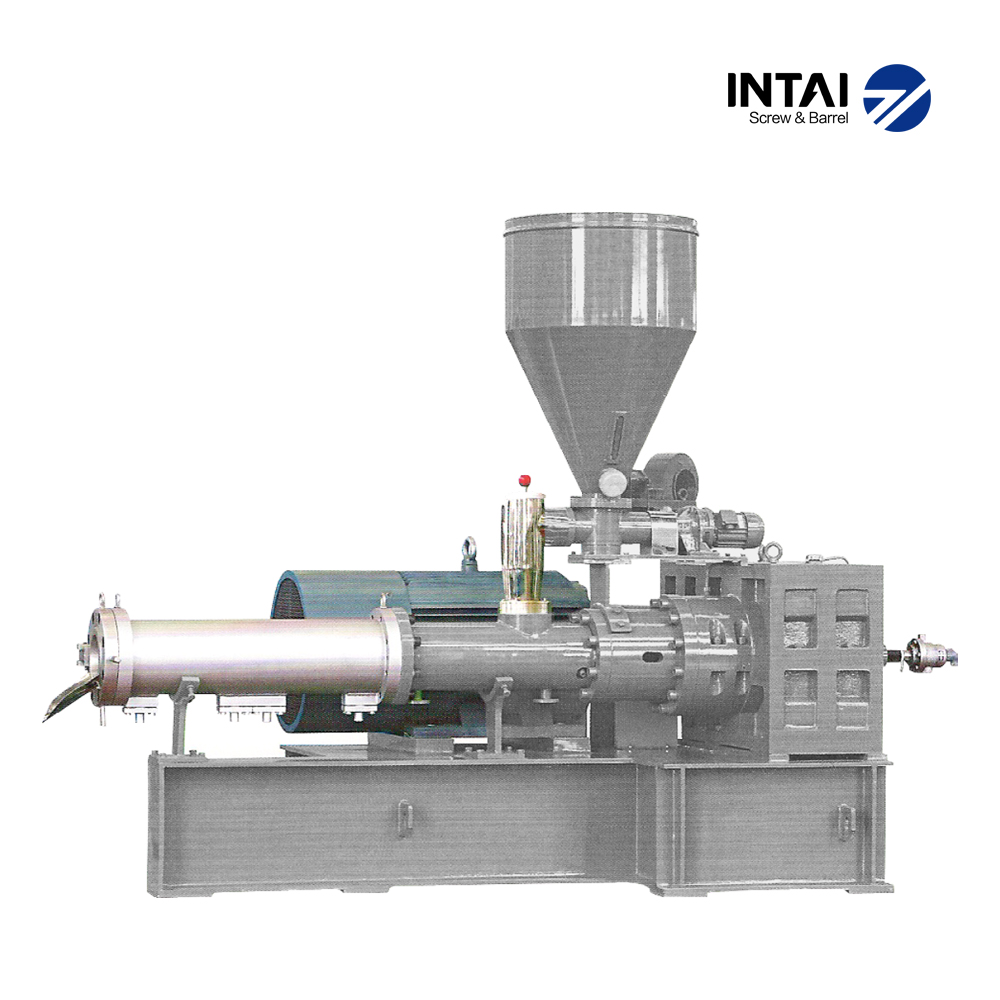

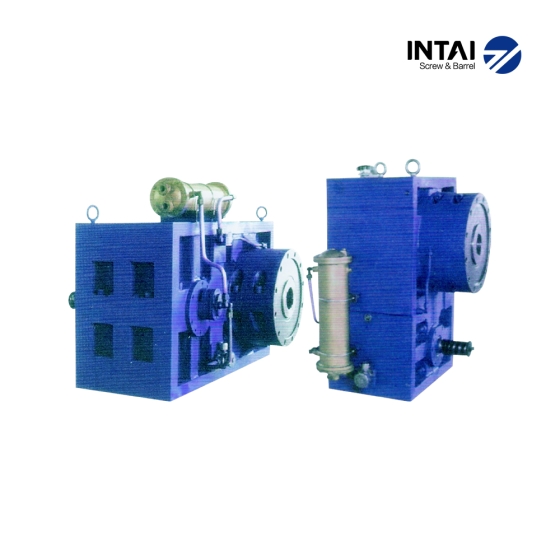

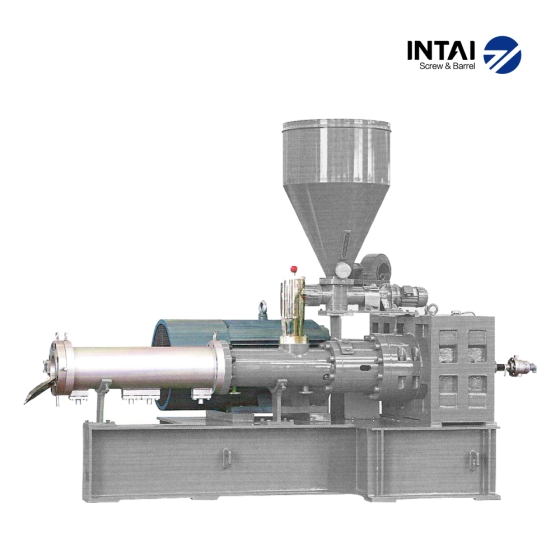

The planetary screw extruder is a specialized machine for producing PVC pipes, profiles, sheets, and films. Its planetary screw design improves mixing and ensures uniform plasticizing. By lowering shear stress, it keeps extrusion stable and improves product consistency. This structure also enhances surface quality and dimensional accuracy, even in high-volume production.

Intai builds planetary screw extruders with alloy steels, CNC machining, and advanced surface treatments such as nitriding and bimetallic coating. These technologies add wear resistance and corrosion protection. The extruder handles a wide range of raw materials, including recycled plastics and high-filler compounds. As a result, manufacturers gain long service life, lower downtime, and reduced costs.

With more than 20 years of industry experience and certifications from CE, TÜV, BSI, and UKAS, Intai delivers extrusion equipment trusted by customers in over 20 countries. See the full range in our مصنوعات catalog, or check ISO Standards for global compliance. Intai keeps innovating, ensuring planetary screw extruders provide reliable performance and meet the changing demands of the plastic processing industry worldwide.

The planetary screw extruder is a specialized machine for producing PVC pipes, profiles, sheets, and films. Its planetary screw design improves mixing and ensures uniform plasticizing. By lowering shear stress, it keeps extrusion stable and improves product consistency. This structure also enhances surface quality and dimensional accuracy, even in high-volume production.

Intai builds planetary screw extruders with alloy steels, CNC machining, and advanced surface treatments such as nitriding and bimetallic coating. These technologies add wear resistance and corrosion protection. The extruder handles a wide range of raw materials, including recycled plastics and high-filler compounds. As a result, manufacturers gain long service life, lower downtime, and reduced costs.

With more than 20 years of industry experience and certifications from CE, TÜV, BSI, and UKAS, Intai delivers extrusion equipment trusted by customers in over 20 countries. See the full range in our مصنوعات catalog, or check ISO Standards for global compliance. Intai keeps innovating, ensuring planetary screw extruders provide reliable performance and meet the changing demands of the plastic processing industry worldwide.

Q1: What materials are used for Intai screw barrels?

A1: We use high-grade alloy steels with nitriding or bimetallic coatings to ensure wear resistance, corrosion protection, and long service life.

Q2: Can you produce customized screw barrels?

A2: Yes, we design and manufacture conical, parallel, single, and bimetallic screw barrels according to customer specifications for extrusion and injection molding.

Q3: What industries and applications are your products suitable for?

A3: Intai screw barrels are widely applied in plastic extrusion and injection, including PVC pipes, profiles, sheets, WPC products, and plastic recycling.

Q4: How long is the delivery time?

A4: Standard models are available within 20–30 days. Customized products depend on specifications, and our team will confirm exact lead time with you.

Q5: Do you provide quality certification?

A5: Yes, our products are certified with CE, TÜV, BSI, and UKAS, and detailed inspection reports can be provided upon request.

انٹائی سکرو تیاری

انٹائی سکرو تیاری