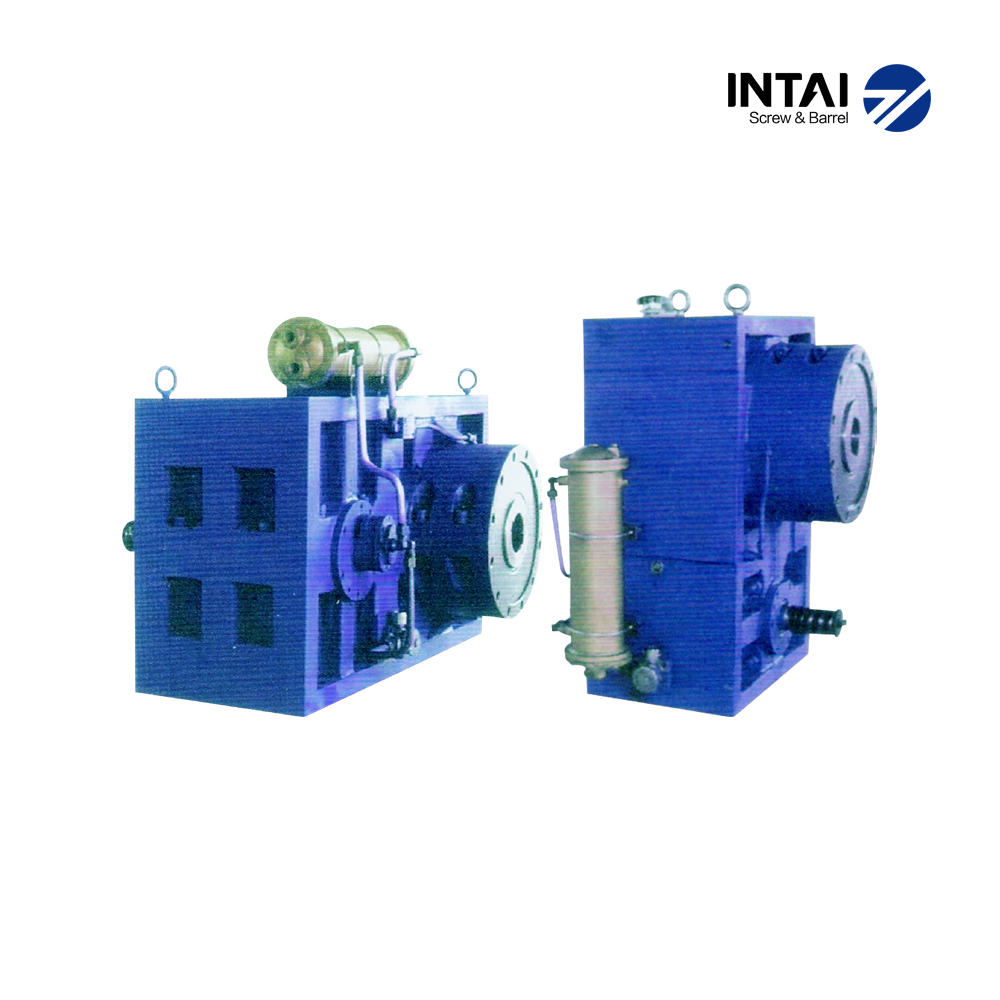

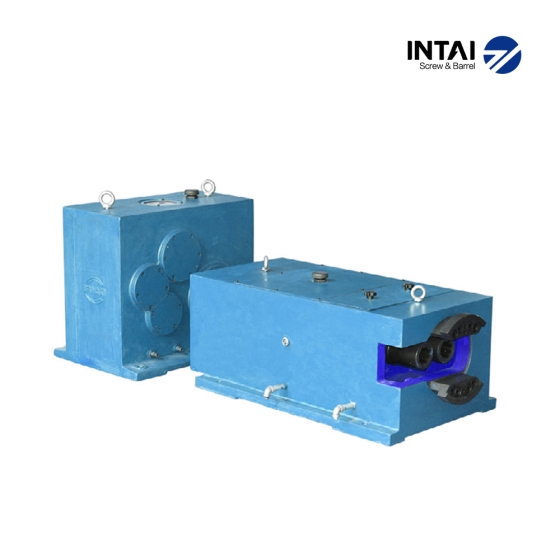

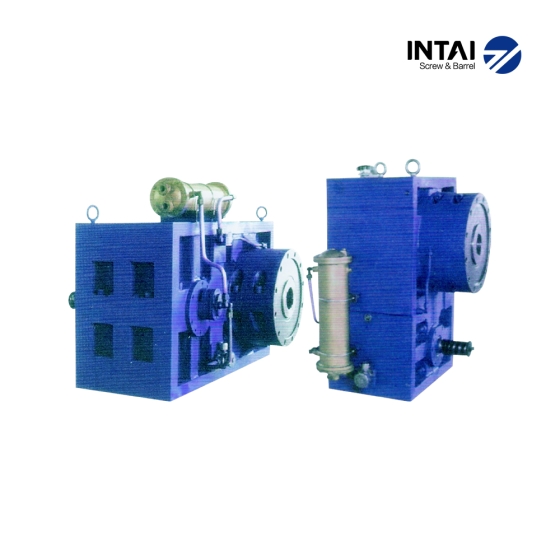

The YTYJ series gearboxes are specially developed for plastic single screw extruders that require stable transmission and high torque performance. With optimized gear geometry and precision machining, they deliver strong load-bearing capacity and smooth operation, even in continuous high-pressure extrusion. The robust structure ensures low noise, efficient power transfer, and reliable service over long production cycles.

Intai manufactures YTYJ gearboxes using advanced alloy steels, strict heat treatment, and CNC machining to guarantee strength, durability, and precision. The gearboxes are equipped with effective cooling and lubrication systems, which improve working efficiency and extend lifespan. They are suitable for extrusion of pipes, plates, sheets, films, and profiles, meeting the needs of various plastic processing applications.

With over 20 years of manufacturing experience and certifications from CE, TÜV, BSI, and UKAS, Intai supplies extrusion gearboxes trusted in more than 20 countries. Explore more extrusion equipment in our Products catalog, or review ISO Standards to learn about international quality requirements. Intai continues to innovate, ensuring that the YTYJ series gearboxes provide reliable performance, cost efficiency, and long-term value for global customers.

Intai Screw Manufacture

Intai Screw Manufacture