初め 製品はプラスチック加工のほぼすべての分野をカバーします. 一般プラスチック製品と精密部品を一括生産するメーカーのニーズに合わせて設計します。. 当社のスクリューおよびバレルのソリューションは押出をサポートします, 射出成形, フィルムブロー, パイプおよび異形押出, シート製造, プラスチックのリサイクルと. この幅広い製品ラインナップにより、, メーカーが安定した生産を維持できるよう支援します, 効率を向上させる, 一貫した品質を実現します.

私たちは構築します INTAI スクリューバレル 先進的な合金鋼を使用, 精密CNC加工, 窒化処理やバイメタルコーティングなどの処理も可能. これらのプロセスによりバレルに耐久性が与えられます, 強い耐摩耗性, そして長寿命. それらはうまく機能します PE, PP, ペット, PVC, ABS, エンジニアリングプラスチック, フィラー入りのリサイクル材料も.

以上 20 長年の経験と認定 CE, テュフ, BSI, とUKAS, Intai は世界中で信頼されるスクリュー バレル ソリューションを提供します. の全範囲をご覧ください 製品 またはレビュー ISO規格 国際品質の詳細については、. 私たちは革新を続けます, 当社の製品が要求の厳しいプラスチック加工用途に対して安定した性能と信頼性を提供できるようにする.

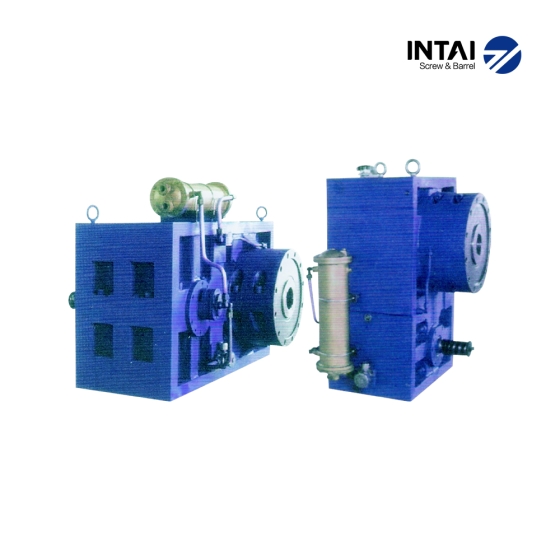

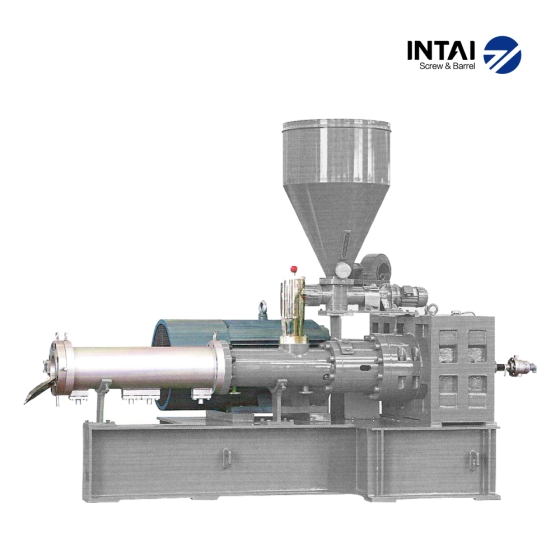

Intaiスクリューの製造

Intaiスクリューの製造