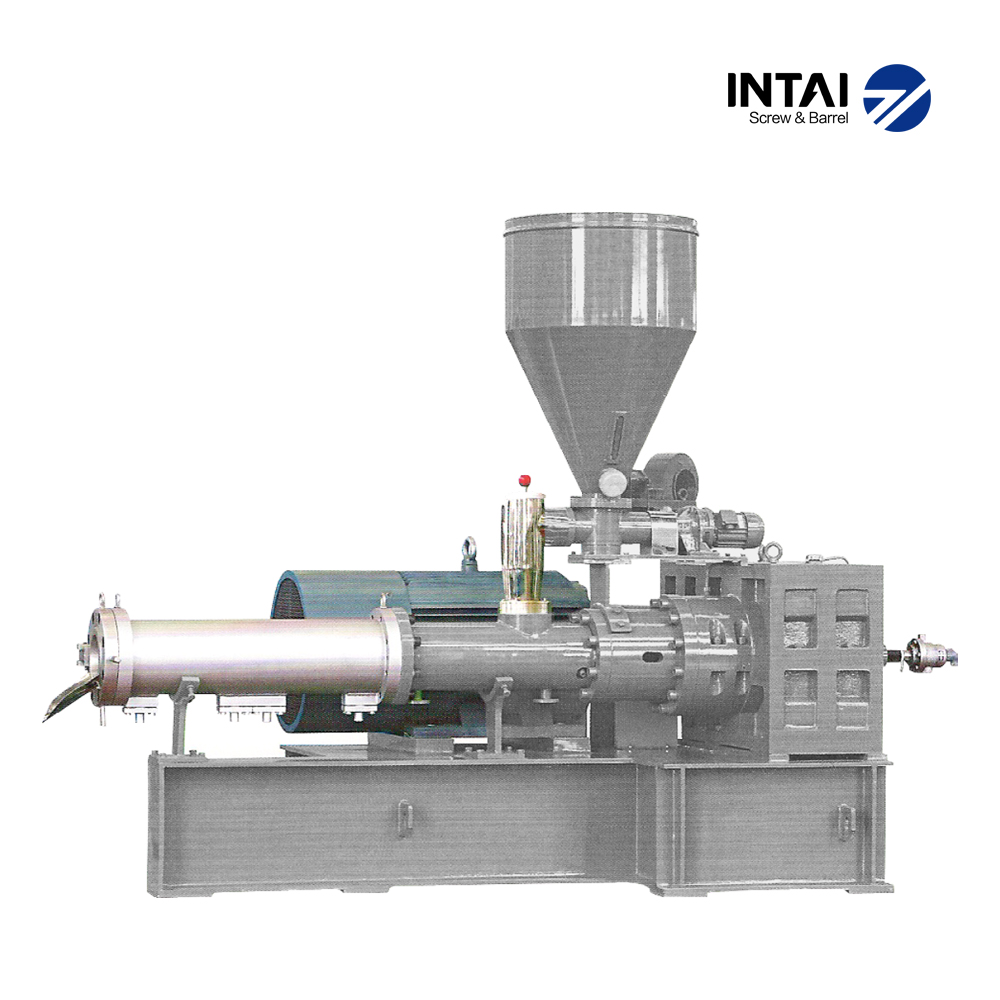

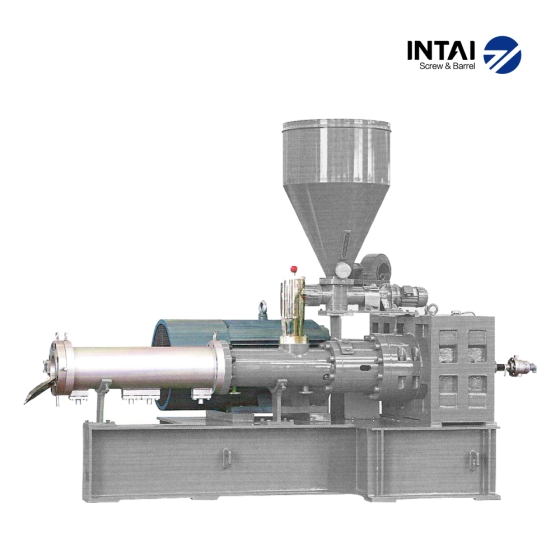

را planetary screw extruder is a specialized machine for producing PVC pipes, پروفایل ها, ورق ها, and films. Its planetary screw design improves mixing and ensures uniform plasticizing. By lowering shear stress, it keeps extrusion stable and improves product consistency. This structure also enhances surface quality and dimensional accuracy, even in high-volume production.

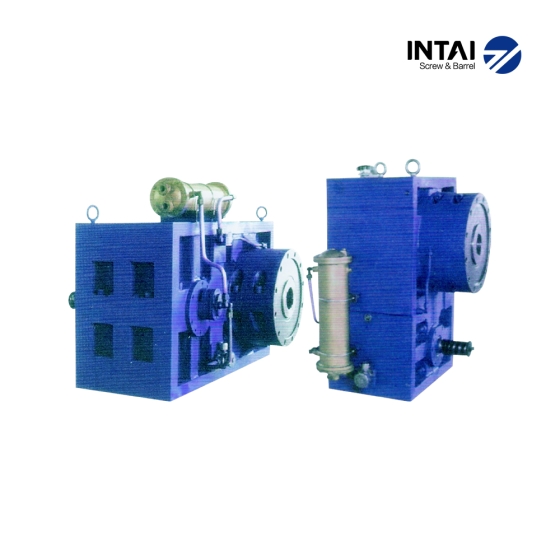

Intai builds planetary screw extruders with alloy steels, CNC machining, and advanced surface treatments such as nitriding and bimetallic coating. These technologies add wear resistance and corrosion protection. The extruder handles a wide range of raw materials, including recycled plastics and high-filler compounds. As a result, manufacturers gain long service life, lower downtime, and reduced costs.

With more than 20 years of industry experience and certifications from CE, TÜV, BSI, و UKAS, Intai delivers extrusion equipment trusted by customers in over 20 کشورها. See the full range in our محصولات کاتالوگ, or check استانداردهای ISO for global compliance. Intai keeps innovating, ensuring planetary screw extruders provide reliable performance and meet the changing demands of the plastic processing industry worldwide.

را planetary screw extruder is a specialized machine for producing PVC pipes, پروفایل ها, ورق ها, and films. Its planetary screw design improves mixing and ensures uniform plasticizing. By lowering shear stress, it keeps extrusion stable and improves product consistency. This structure also enhances surface quality and dimensional accuracy, even in high-volume production.

Intai builds planetary screw extruders with alloy steels, CNC machining, and advanced surface treatments such as nitriding and bimetallic coating. These technologies add wear resistance and corrosion protection. The extruder handles a wide range of raw materials, including recycled plastics and high-filler compounds. As a result, manufacturers gain long service life, lower downtime, and reduced costs.

With more than 20 years of industry experience and certifications from CE, TÜV, BSI, و UKAS, Intai delivers extrusion equipment trusted by customers in over 20 کشورها. See the full range in our محصولات کاتالوگ, or check استانداردهای ISO for global compliance. Intai keeps innovating, ensuring planetary screw extruders provide reliable performance and meet the changing demands of the plastic processing industry worldwide.

Q1: چه موادی برای بشکه های پیچ اینتای استفاده می شود?

A1: ما از فولادهای آلیاژی با عیار بالا با پوشش های نیترید یا دو فلزی برای اطمینان از مقاومت در برابر سایش استفاده می کنیم, حفاظت در برابر خوردگی, و عمر طولانی.

Q2: آیا می توانید بشکه های پیچ سفارشی تولید کنید?

A2: بله, ما مخروطی را طراحی و تولید می کنیم, موازی, مجرد, و بشکه های پیچ دو فلزی مطابق با مشخصات مشتری برای قالب گیری اکستروژن و تزریق.

Q3: محصولات شما برای چه صنایع و کاربردهایی مناسب هستند?

A3: بشکه پیچ Intai به طور گسترده در اکستروژن و تزریق پلاستیک استفاده می شود, از جمله لوله های پی وی سی, پروفایل ها, ورق ها, محصولات WPC, و بازیافت پلاستیک.

Q4: مدت زمان تحویل چقدر است?

A4: مدل های استاندارد ظرف 20 تا 30 روز در دسترس هستند. محصولات سفارشی به مشخصات بستگی دارد, و تیم ما زمان دقیق را با شما تایید خواهد کرد.

Q5: آیا گواهی کیفیت ارائه می دهید؟?

A5: بله, محصولات ما دارای گواهی CE هستند, TÜV, BSI, و UKAS, و گزارش تفصیلی بازرسی می تواند در صورت درخواست ارائه شود.

ساخت پیچ اینتای

ساخت پیچ اینتای