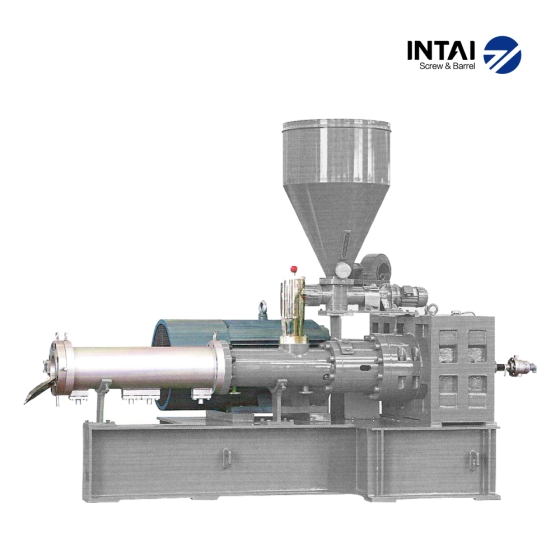

El single screw plastic extruder is one of the most versatile machines in plastic processing. It is suitable for producing educación física, PP, PET, PVC, and ABS products, including pipes, hojas, películas, and granules. With its simple design and reliable structure, the extruder offers stable performance, high output, and strong adaptability to different raw materials.

Intai single screw extruders are manufactured with aceros aleados, precision CNC machining, y tratamientos superficiales avanzados como nitruración y recubrimiento bimetálico. These processes improve wear resistance, enhance corrosion protection, and extend service life. The design ensures efficient plasticizing, consistent melting, and uniform extrusion, helping manufacturers achieve stable production and reduce costs.

Equipped with modern control systems, the machine supports energy-saving operation and precise adjustment for different production needs. It is especially effective for film extrusion, pipe production, and recycling applications.

con más 20 años de experiencia y certificaciones de CE, TUV, BSI, y UKAS, Intai provides extrusion equipment trusted in more than 20 países. Explore our Productos catalog for more extrusion solutions, o revisar Normas ISO to understand international compliance. Intai sigue innovando, offering reliable single screw plastic extruders that meet the evolving demands of the plastic processing industry.

Fabricación de tornillos Intai

Fabricación de tornillos Intai