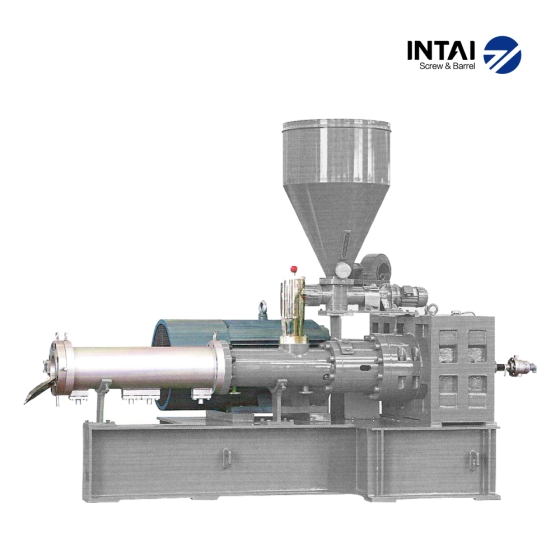

Single screw & barrel is one of the most widely used components in plastic extrusion and injection molding. It is suitable for processing educación física, PP, PET, PVC, and other thermoplastic materials. With its simple yet efficient design, the single screw barrel offers stable extrusion, precise plasticizing, and strong conveying ability. This ensures high output, consistent product dimensions, and reliable surface quality for various plastic products.

El single screw barrel structure provides flexibility for different applications, including film extrusion, pipe extrusion, sheet production, and injection molding. It is especially valued for its straightforward design, easy operation, and strong adaptability to different raw materials and production requirements.

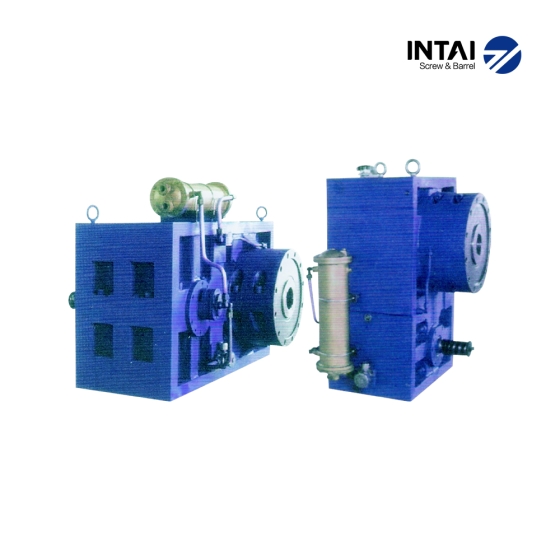

Intai manufactures single screw barrels with high-quality alloy steels, Mecanizado CNC, and advanced treatments such as nitriding, hard chrome plating, and bimetallic coating. These processes significantly enhance wear resistance and corrosion protection, extending service life even under high-temperature and high-pressure conditions.

Each screw barrel undergoes strict quality inspection from raw material selection to final testing. con más 20 years of manufacturing experience and certifications including CE, TUV, BSI, y UKAS, Intai guarantees reliable performance and durability.

Con la confianza de los clientes en más de 20 países, Intai single screw & barrel provides efficient solutions for global extrusion and injection applications. Explore more in our Productos catalog or learn about ISO standards.

Fabricación de tornillos Intai

Fabricación de tornillos Intai