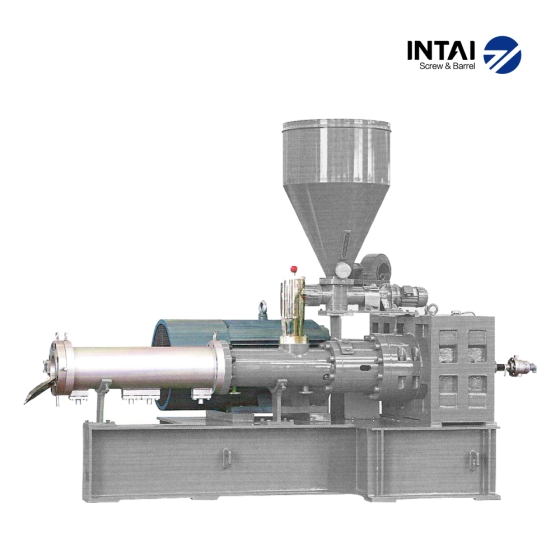

Parallel twin screw & barrel is a widely used component in plastic extrusion, suitable for producing PVC, educación física, ABS, y productos WPC. With its parallel design, the screw offers strong feeding ability, stable plasticizing, and excellent mixing performance. These features ensure consistent extrusion pressure, high output, and reliable quality of finished products.

Compared with conical designs, el parallel twin screw barrel provides longer effective screw length and a more balanced structure. This design is ideal for applications requiring large capacity and uniform melting of raw materials. It helps manufacturers achieve efficient production while maintaining dimensional accuracy and surface quality of extruded pipes, hojas, y perfiles.

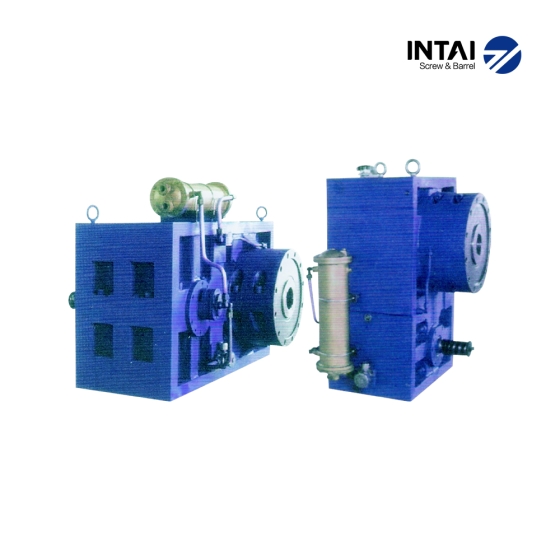

Intai manufactures parallel twin screw barrels using aceros aleados, Mecanizado CNC, y tratamientos superficiales avanzados como nitruración y recubrimiento bimetálico. These processes improve wear resistance and corrosion protection, extending the service life of the screw barrel under demanding extrusion conditions.

Our products undergo strict quality control at every stage, from raw material inspection to final testing. con más 20 years of experience and international certifications including CE, TUV, BSI, y UKAS, Intai provides customers with reliable extrusion solutions trusted in more than 20 países.

Discover more in our Productos catalog or learn about ISO standards for global quality assurance.

Fabricación de tornillos Intai

Fabricación de tornillos Intai