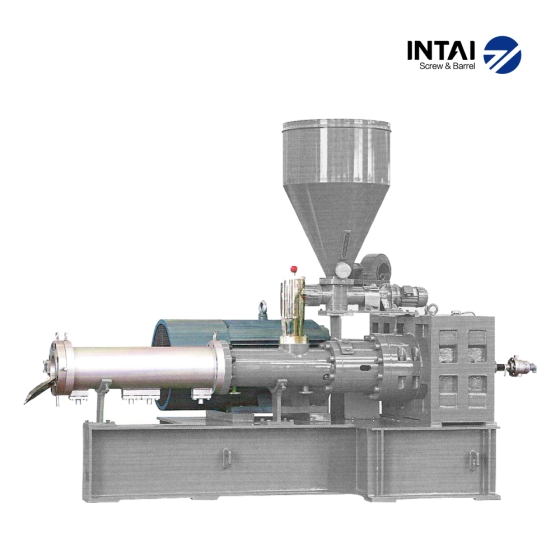

Conical twin screw & barrel is widely used for producing PVC powder materials. It shows clear advantages in processing UPVC dry mixed powder products and in PVC granulation. With its special conical design, the screw increases plasticizing capacity and significantly improves the output of the extruder. This makes it an ideal solution for manufacturers who require both efficiency and consistent quality in plastic extrusion.

Compared with parallel twin screws, the conical twin screw barrel provides a stronger compression ratio and more stable feeding performance. This ensures efficient melting, uniform mixing, and better plasticization of raw materials. The result is improved extrusion quality and a reduction in defects for finished PVC products.

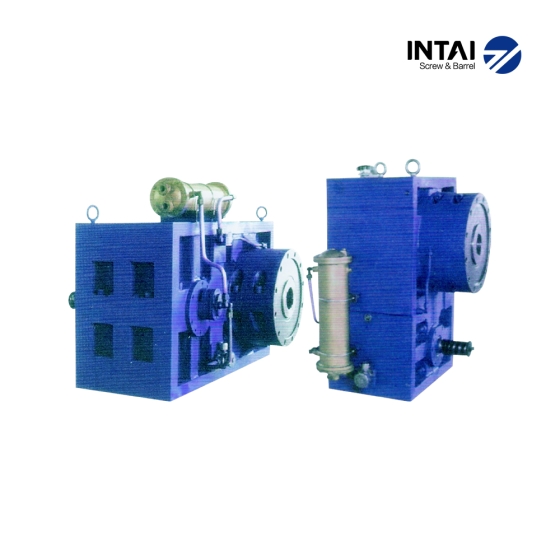

Intai has developed its own SKD barrel series, designed specifically for extreme working conditions. This series can handle super high wear materials with a filling ratio between 50% y 300%, making it suitable for demanding applications where durability is critical. Advanced alloy steels, Mecanizado CNC, and surface treatments such as nitriding and bimetallic coating ensure outstanding wear resistance and long service life.

Every conical twin screw barrel produced by Intai undergoes strict quality control from raw material inspection to final testing. con más de 20 years of experience, Intai provides extrusion solutions trusted in more than 20 países. To explore more Productos, visit our catalog. For global standards reference, see ISO.

Fabricación de tornillos Intai

Fabricación de tornillos Intai