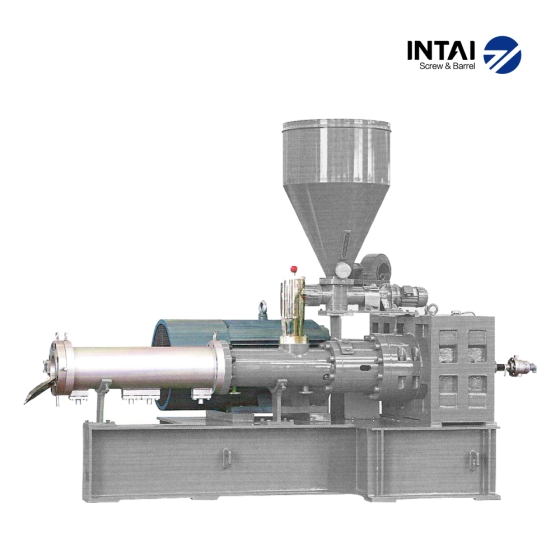

Bimetallic screw & barrel is built for demanding extrusion and injection applications that require high wear resistance and strong corrosion protection. Intai fuses a durable alloy inner layer with a tough outer steel base. This design handles high filler compounds, recycled plastics, and abrasive raw materials while keeping stable output. It extends service life, reduces downtime, and helps manufacturers maintain consistent quality.

We use CNC precision machining, nitriding, and advanced coating to produce each barril de tornillo bimetálico. These processes give the barrel high hardness, smooth surfaces, and reliable strength under high pressure and high temperature. The result is efficient plasticizing, steady extrusion, and lower maintenance costs.

con más 20 años de experiencia y certificaciones de CE, TUV, BSI, y UKAS, Intai supplies screw and barrel solutions trusted in more than 20 países. Check our full Productos catalog to explore the range. You can also review Normas ISO to understand global quality requirements. Intai keeps innovating to provide bimetallic screw & barrel products that deliver durability, reliability, and efficiency in plastic processing worldwide.

Fabricación de tornillos Intai

Fabricación de tornillos Intai