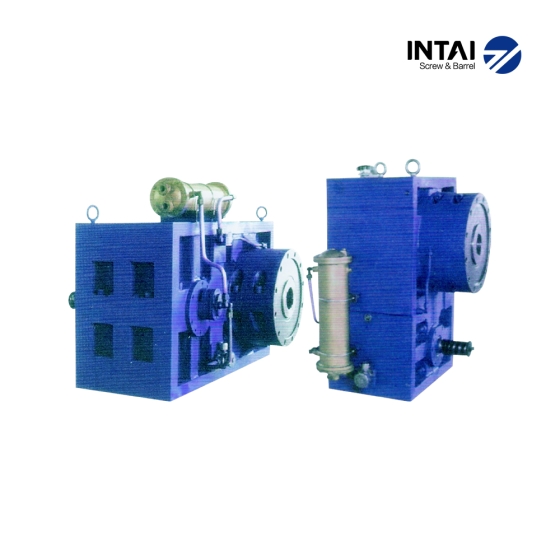

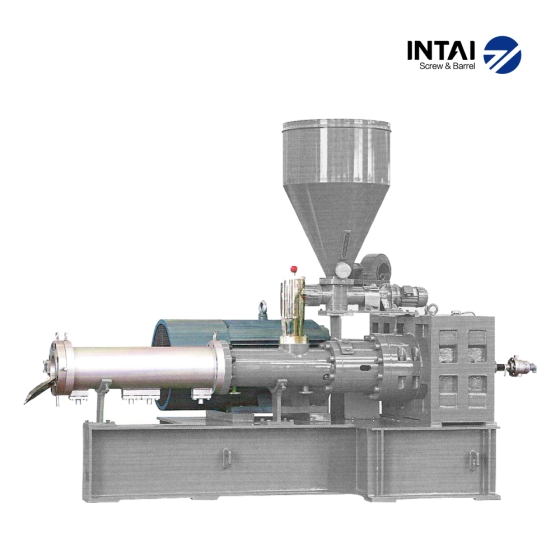

Der YTSZ series twin screw extruder gearbox is designed for both conical and parallel twin screw extruders. It delivers high torque, stable power transmission, and reliable performance. Mit optimierter Zahnradgeometrie und Präzisionsbearbeitung, it handles heavy loads and continuous operation in demanding extrusion lines. Manufacturers use it widely in PVC-Rohre, Profile, Blätter, and WPC production, where stable output and accurate control are essential.

Intai builds YTSZ gearboxes with CNC-Bearbeitung, heat treatment, and strict quality checks. These processes give the gearbox high strength, precise alignment, und lange Lebensdauer. We also equip each unit with advanced cooling and lubrication systems. They prevent overheating and ensure smooth operation during long production runs. The sealing system provides reliable protection against leaks, which reduces downtime and lowers maintenance costs.

Mit vorbei 20 years of experience and certifications from CE, TÜV, BSI, und UKAS, Intai supplies gearboxes trusted in more than 20 Länder. See the full range of equipment in our Produkte Katalog, oder überprüfen ISO-Standards for international compliance. Intai continues to improve gearbox technology, delivering efficient, durable, and cost-effective solutions for global plastic processing industries.

Herstellung von Intai-Schrauben

Herstellung von Intai-Schrauben