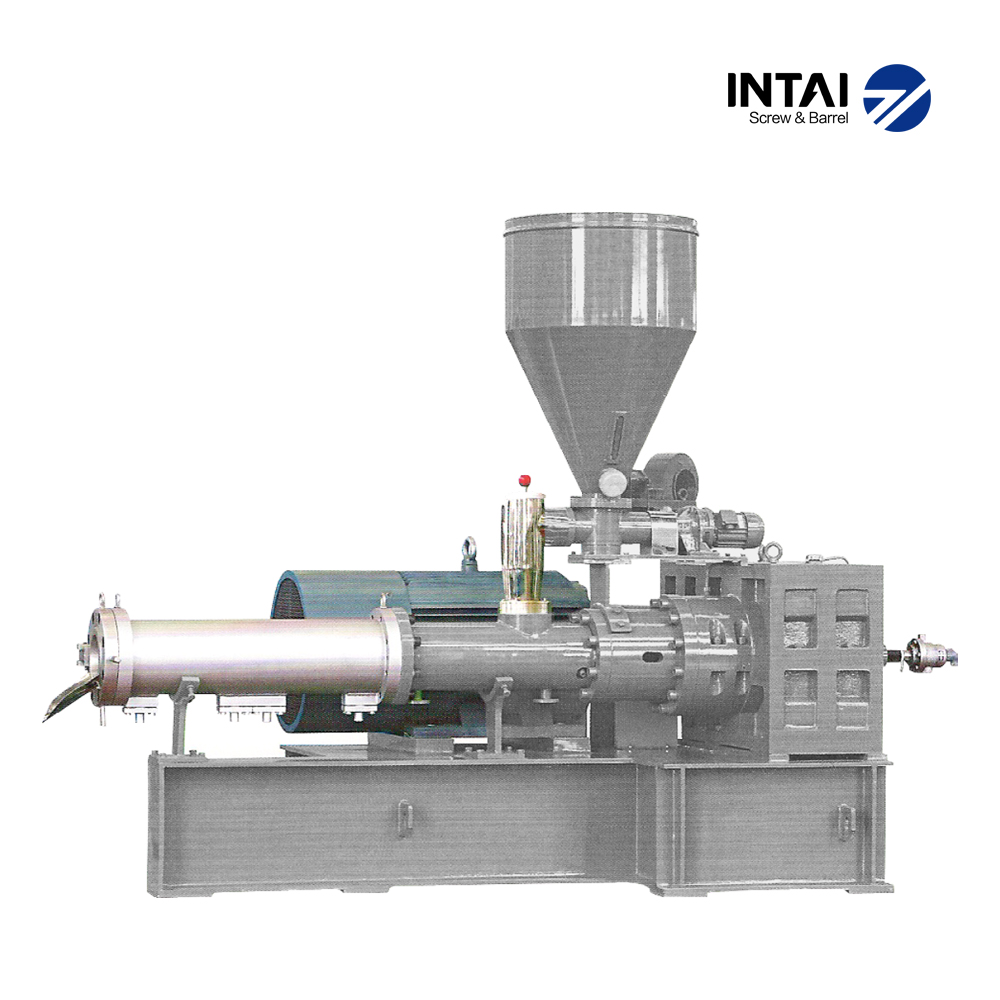

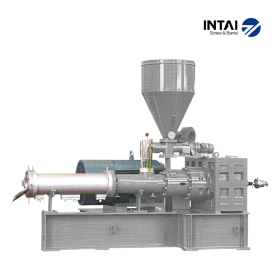

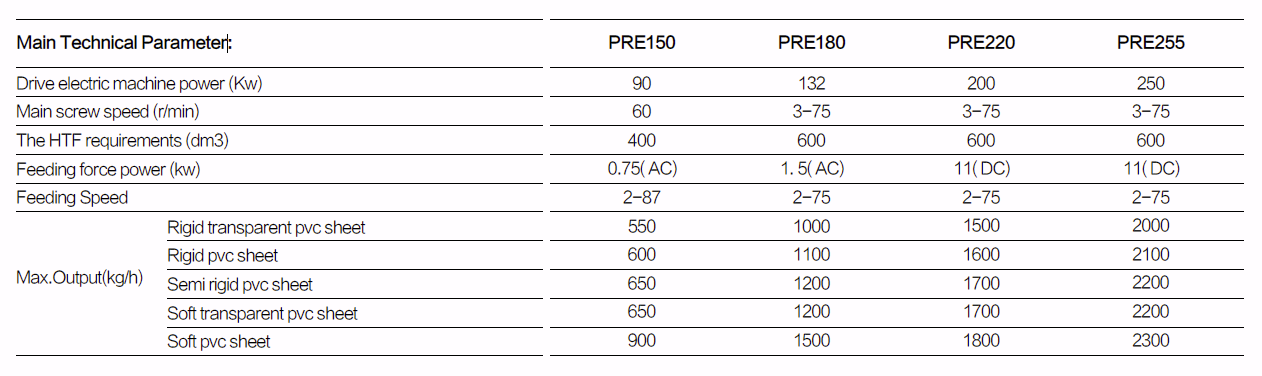

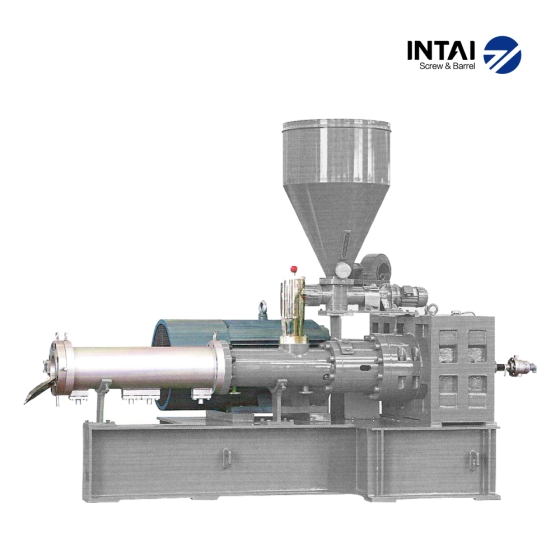

The planetary screw extruder is a specialized machine for producing PVC pipes, الملفات الشخصية, أوراق, and films. Its planetary screw design improves mixing and ensures uniform plasticizing. By lowering shear stress, it keeps extrusion stable and improves product consistency. This structure also enhances surface quality and dimensional accuracy, even in high-volume production.

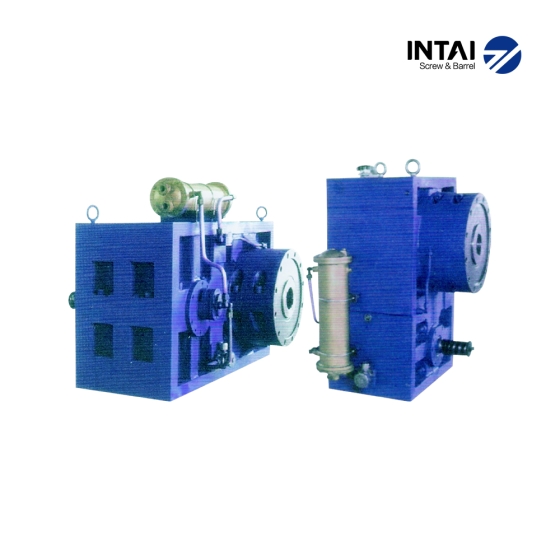

Intai builds planetary screw extruders with alloy steels, التصنيع باستخدام الحاسب الآلي, and advanced surface treatments such as nitriding and bimetallic coating. These technologies add wear resistance and corrosion protection. The extruder handles a wide range of raw materials, including recycled plastics and high-filler compounds. As a result, manufacturers gain long service life, lower downtime, and reduced costs.

مع أكثر من 20 years of industry experience and certifications from م, توف, بي إس آي, و UKAS, Intai delivers extrusion equipment trusted by customers in over 20 بلدان. See the full range in our المنتجات catalog, or check معايير الأيزو for global compliance. Intai keeps innovating, ensuring planetary screw extruders provide reliable performance and meet the changing demands of the plastic processing industry worldwide.

The planetary screw extruder is a specialized machine for producing PVC pipes, الملفات الشخصية, أوراق, and films. Its planetary screw design improves mixing and ensures uniform plasticizing. By lowering shear stress, it keeps extrusion stable and improves product consistency. This structure also enhances surface quality and dimensional accuracy, even in high-volume production.

Intai builds planetary screw extruders with alloy steels, التصنيع باستخدام الحاسب الآلي, and advanced surface treatments such as nitriding and bimetallic coating. These technologies add wear resistance and corrosion protection. The extruder handles a wide range of raw materials, including recycled plastics and high-filler compounds. As a result, manufacturers gain long service life, lower downtime, and reduced costs.

مع أكثر من 20 years of industry experience and certifications from م, توف, بي إس آي, و UKAS, Intai delivers extrusion equipment trusted by customers in over 20 بلدان. See the full range in our المنتجات catalog, or check معايير الأيزو for global compliance. Intai keeps innovating, ensuring planetary screw extruders provide reliable performance and meet the changing demands of the plastic processing industry worldwide.

س1: ما هي المواد المستخدمة لبراميل المسمار Intai?

أ1: نحن نستخدم سبائك فولاذية عالية الجودة مع طلاءات نيتريدية أو ثنائية المعدن لضمان مقاومة التآكل, الحماية من التآكل, وعمر الخدمة الطويل.

Q2: هل يمكنك إنتاج براميل لولبية مخصصة?

A2: نعم, نقوم بتصميم وتصنيع المخروطية, موازي, أعزب, والبراميل اللولبية ثنائية المعدن وفقًا لمواصفات العميل الخاصة بالبثق والحقن.

س3: ما هي الصناعات والتطبيقات التي تناسب منتجاتك؟?

A3: يتم تطبيق البراميل اللولبية Intai على نطاق واسع في بثق وحقن البلاستيك, بما في ذلك الأنابيب البلاستيكية, الملفات الشخصية, أوراق, منتجات WPC, وإعادة تدوير البلاستيك.

س 4: كم من الوقت هو وقت التسليم?

A4: النماذج القياسية متاحة خلال 20-30 يومًا. المنتجات المخصصة تعتمد على المواصفات, وسيقوم فريقنا بتأكيد المهلة المحددة معك.

س5: هل تقدم شهادة الجودة?

A5: نعم, منتجاتنا معتمدة مع CE, توف, بي إس آي, و UKAS, ويمكن تقديم تقارير التفتيش التفصيلية عند الطلب.

تصنيع المسمار إنتاي

تصنيع المسمار إنتاي