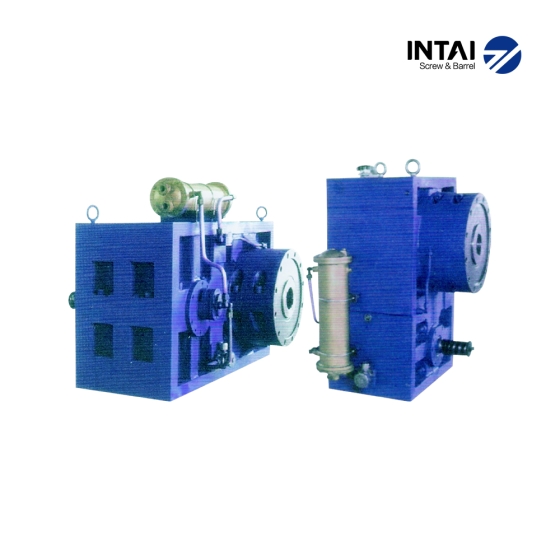

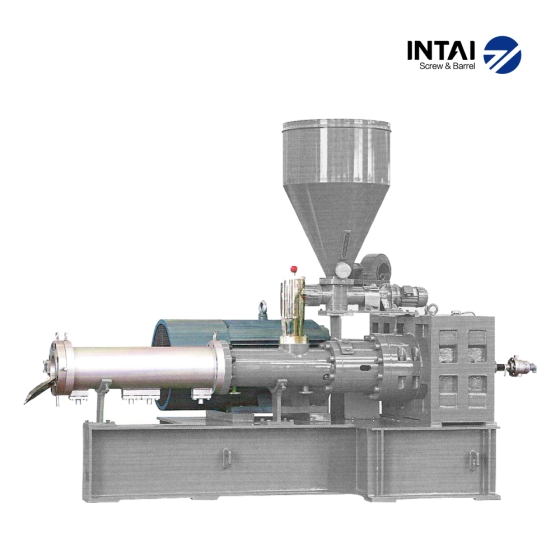

المسمار ثنائية المعدن & برميل تم تصميمه لتطبيقات البثق والحقن الصعبة التي تتطلب مقاومة عالية للتآكل وحماية قوية من التآكل. تدمج Intai طبقة داخلية من السبائك المتينة مع قاعدة فولاذية خارجية صلبة. يعالج هذا التصميم مركبات حشو عالية, البلاستيك المعاد تدويره, والمواد الخام الكاشطة مع الحفاظ على إنتاج مستقر. إنه يمتد عمر الخدمة, يقلل من وقت التوقف عن العمل, ويساعد الشركات المصنعة على الحفاظ على جودة ثابتة.

نحن نستخدم الآلات الدقيقة باستخدام الحاسب الآلي, نيترة, وطلاء متقدم لإنتاج كل منها برميل المسمار ثنائية المعدن. هذه العمليات تعطي البرميل صلابة عالية, الأسطح الملساء, وقوة موثوقة تحت الضغط العالي ودرجة الحرارة العالية. والنتيجة هي التلدين الفعال, قذف ثابت, وانخفاض تكاليف الصيانة.

مع أكثر 20 سنوات من الخبرة والشهادات من م, توف, بي إس آي, و UKAS, توفر شركة Intai حلولاً للبراغي والبراميل موثوق بها في أكثر من 20 بلدان. تحقق لدينا الكامل المنتجات كتالوج لاستكشاف النطاق. يمكنك أيضًا المراجعة معايير الأيزو لفهم متطلبات الجودة العالمية. تواصل Intai الابتكار لتوفير المسمار ثنائي المعدن & منتجات برميلية توفر المتانة, مصداقية, والكفاءة في معالجة البلاستيك في جميع أنحاء العالم.

تصنيع المسمار إنتاي

تصنيع المسمار إنتاي